to reduce your part production costs.

Make your induction hardening

more profitable

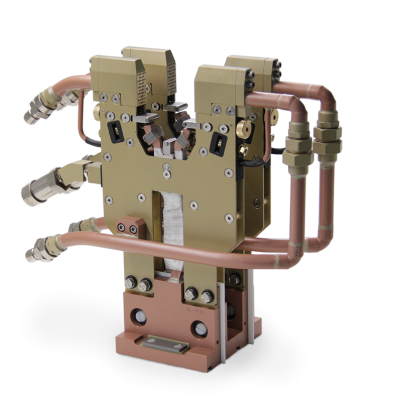

The 3D additive manufacturing era is here, and that applies to the induction world too. GH is the first induction heating group deploying hundreds of 3D printed coils since 2014.

Our induction experience and a field-proven and patented 3D printing coil technology (3DPCoil) based on EBM makes GH 3D inductors the safest investment.

3DINDUCTORS

A unique pure copper

3D printing technology

EXTRAORDINARY

SERVICE LIFE

Total Cost of Ownership decrease

Lower Inventory

Minimized Stoppages

DESIGN

FLEXIBILITY

Continuous improvement

Complex shapes

Cooling optimization

TOTALLY

REPEATABLE

Simplified changeovers

Planned production

Identical inductors

Benefits

Progress is not an illusion... it happens.

1

PART PRODUCTION

COST REDUCTION

Extraordinary increase of heating cycles with the same inductor. At least double production volume.

The cost per part and the inductor stock are reduced. Total Cost of Ownership (TCO) of an induction installation is minimized.

EXTRAORDINARY

LIFESPAN

Strengths compared to current coil manufacturing methods:

- 3D printing without brazed joints and leakages.

- Improved inner cooling due to the design flexibility.

- Pure copper raw material.

2

STOPPAGES &

CHANGEOVERS MINIMISED

As the inductor life is much higher and the inductors are identical, the hardening machine stoppages are reduced, changeovers are simpler and the production planning is more controlled. Repairable as traditional coils.

TOTALLY

REPEATABLE

Always the same coil:

- Industrialized process. No human influence.

- From CAD design file to direct printing.

- Without porosity

3

CONTINUOUS

IMPROVEMENT

The original 3DPCoil design can be optimized after each changeover due to the industrialized process and coil design flexibility.

Strengthening of high intensity zones, profile adjustments, etc. are feasible.

DESIGN

FLEXIBILITY

What the traditional brazed coils do not achieve:

- Powder melting instead of tube machining

- Internal and external geometry modifications

More than printing

We accompany you in the process of incorporating 3D inductors on your production lines.

With more than half a century of experience in solutions for induction processes we can help you beyond the supply of the inductor. We can simulate, design, manufacture, test and work with you on the continuous improvement for inductors and processes.

"Impressive service life"

Do you have any question?

We want to advise you personally regarding your needs